Chamfer Callout Drawing

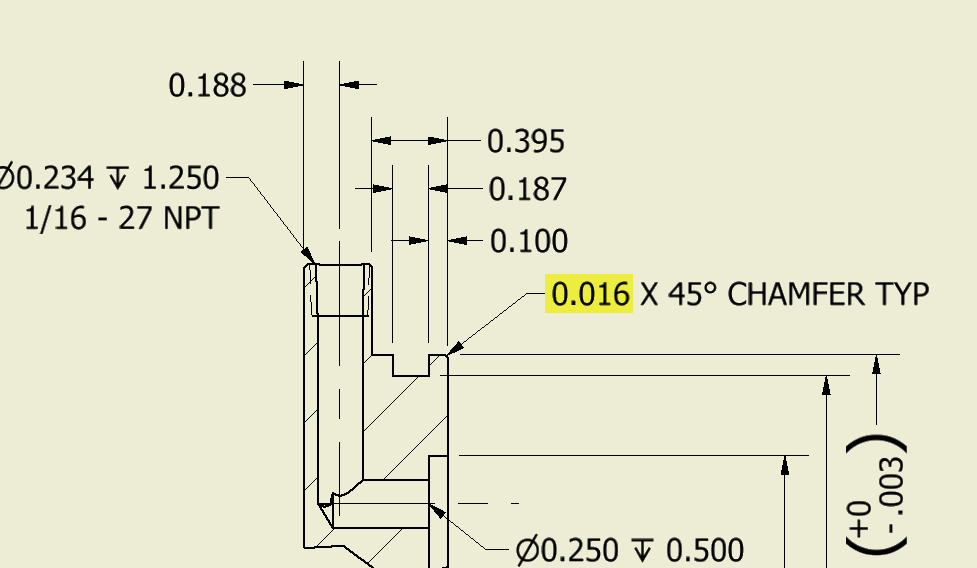

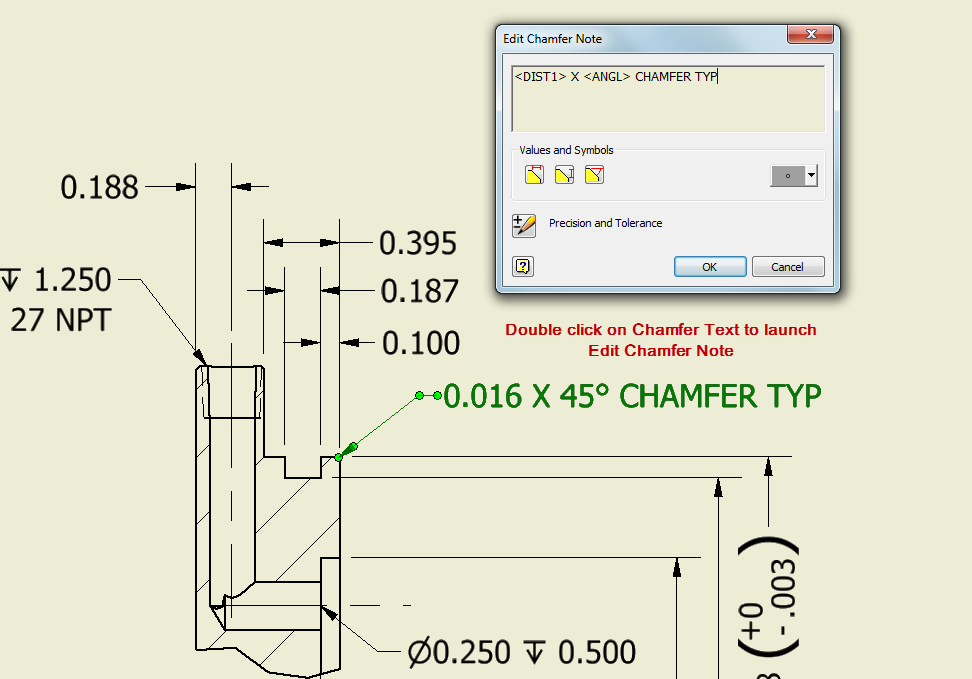

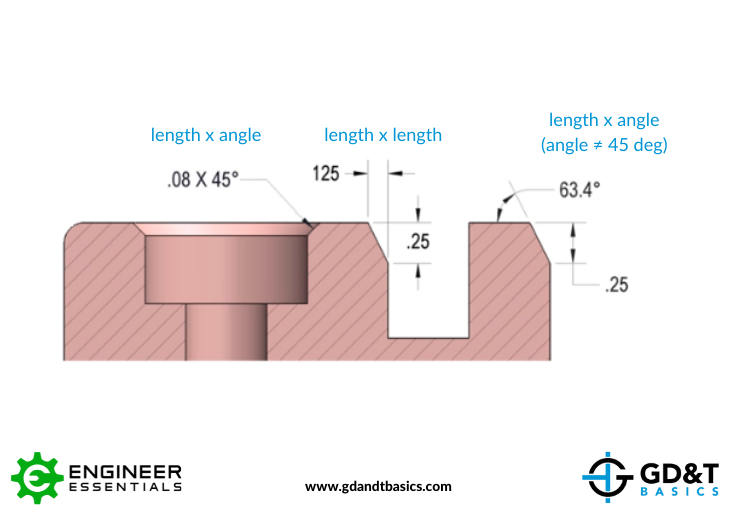

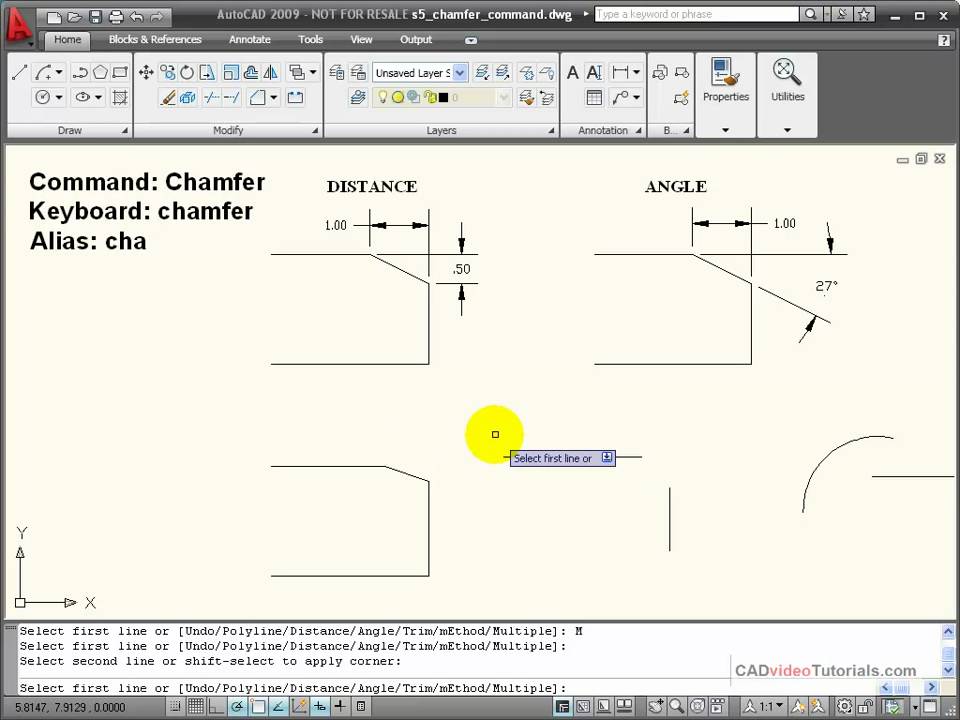

Chamfer Callout Drawing - Drag to place the callout. Web break edge callouts are specified directly on the drawing to reference a certain surface or as a note e.g. Threads are the major geometrical shapes of screws and screw holes. Is it customary to use a dash? Then select one of the lines at the end of your chamfer, then select the line of the edge of the chamfer. You must select the chamfered edge first. Web 26 sep 05 14:51 i have a cylindrical part with a chamfer at each end. Click chamfer dimension on the dimensions/relations toolbar or click tools > dimensions > chamfer. Dimensions are required for points, lines, and surfaces that are related functionally or control relationship of other features. If you created the chamfer using the chamfer feature, simply show your dimensions for that feature or view. Web have you ever seen a 1x1 chamfer called out as c1 on a drawing? You must select the chamfered edge first. See figure 2 for chamfer dimensioning examples. If the selection was part of a hole feature, the precision, tolerance, fit class tolerance, and shaft class tolerance values from that feature are automatically applied. 4x 3 x 45deg seems. Web you can dimension chamfers in drawings. Web to insert chamfer dimensions into a drawing: Dimensioning the threads in technical drawings. Ensure that you select a point close to the desired start point of the chamfer, as your selection point determines the default angle. Select the first chamfer reference, such as a point on a model edge or draft entity. Basic dimensioning is the addition of only functional size values to drawing entities. All of the basic components of an engineering drawing are detailed below with links throughout to. Web apr 19, 2016 03:45 pm. Is it to call out the note with a leader (.25 x 45°) or to add two seperate dimensions (one linear and chamfer callout? Dimensions. For structural i have previously. Web may 5, 2022 by brandon fowler learning to read blueprints can be hard. 4x 3 x 45deg seems a bit confusing. Web to make the dimension callout like your picture, select the perpindicular option on the chamfer dimensioning tool dropdown menu. Also, if you have multiple fillets, which format would be correct? From the chamfer dialog box, select the. If the selection was part of a hole feature, the precision, tolerance, fit class tolerance, and shaft class tolerance values from that feature are automatically applied. Threads are the major geometrical shapes of screws and screw holes. That’s why we’ve broken down the process into bite size chunks. Mechanical engineer sw2005 sp 4.0. This opens the chamfer dialog box. Web you can dimension chamfers in drawings. Is this correct or do i have it backwards? Web since threading often produces starting burrs, these can be minimized by specifying a 45° countersink or chamfer which is.015″ minimum larger than the major diameter on internal threads (see figure 4) and.015″ minimum smaller than the minor. Is it customary to use a dash? 4x r5, or r5 4x? Web to insert chamfer dimensions into a drawing: Web to insert chamfer dimensions into a drawing: Dimensions are required for points, lines, and surfaces that are related functionally or control relationship of other features. If the selection was part of a hole feature, the precision, tolerance, fit class tolerance, and shaft class tolerance values from that feature are automatically applied. Click chamfer dimension on the dimensions/relations toolbar or click tools > dimensions > chamfer. You must select the chamfered edge first. If machinery has screw holes or screws they must be dimensioned properly. Is. There are two schools of thought on whether a chamfer and. Web to make the dimension callout like your picture, select the perpindicular option on the chamfer dimensioning tool dropdown menu. Is this correct or do i have it backwards? Web may 5, 2022 by brandon fowler learning to read blueprints can be hard. Is it to call out the. Web apr 19, 2016 03:45 pm. In addition to the usual dimension display properties, chamfer dimensions have their own options for leader display, text display, and x display. Web chamfers can be dimensioned in two ways, either by calling out the length by angle, or calling out the length by length. Web dimensioning chamfers is done with a call out. Ewh (aerospace) 19 jul 06 11:18 S —surface form can be called out on a drawing in one of two ways. Is this correct or do i have it backwards? You just need to give the length of one edge and the corresponding angle to it. 4x 3 x 45deg seems a bit confusing. Web apr 19, 2016 03:45 pm. Select the first chamfer reference, such as a point on a model edge or draft entity. Select a circle that is part of a hole feature, or a thread that is part of an external thread feature. Then select the edges, features, or faces to chamfer. Web chamfers can be dimensioned in two ways, either by calling out the length by angle, or calling out the length by length. There are two schools of thought on whether a chamfer and. Mechanical engineer sw2005 sp 4.0 & pro/e 2001 dell precision 370 p4 3.6 ghz, 1gb. That should result in what you have shown. You can also click legacy sketch > chamfer. Also, if you have multiple fillets, which format would be correct? See figure 2 for chamfer dimensioning examples.

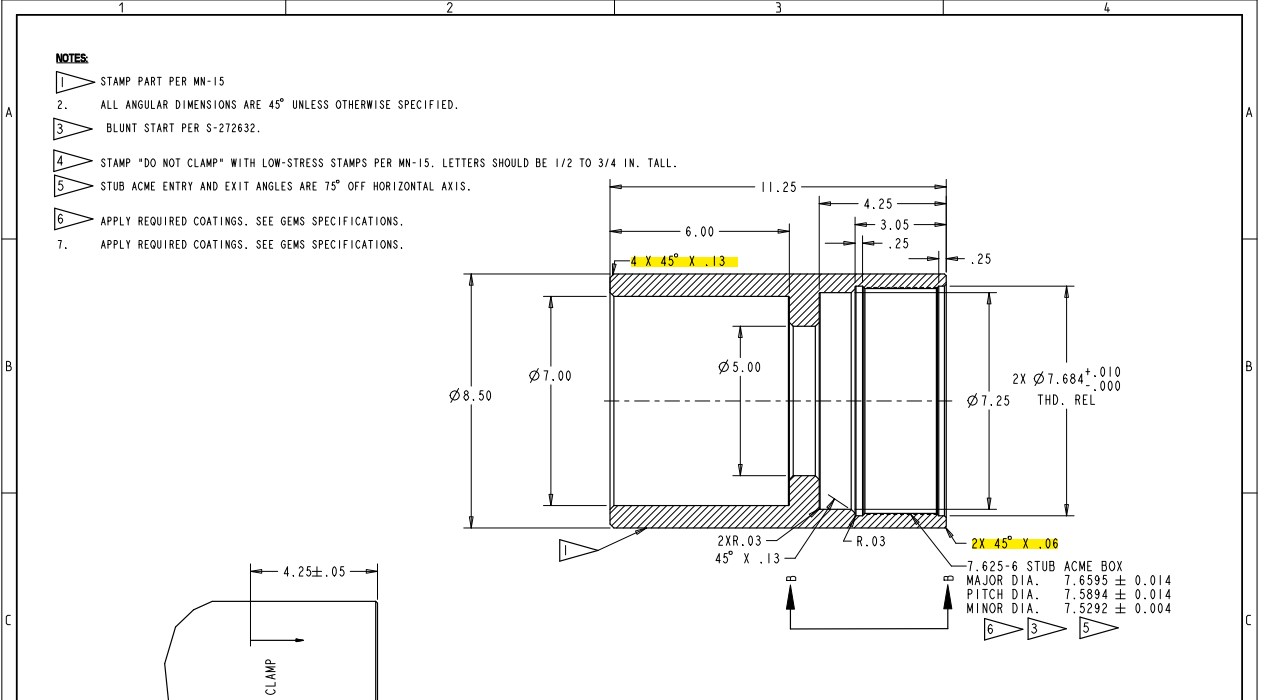

Chamfer Dimensioning GD&T Basics

AutoCAD Tutorial Using the CHAMFER Command YouTube

Inventor Ability to change the decimal places in the call out of the

Dimensioning Chamfers YouTube

Adding a Chamfer Dimension YouTube

SolidWorks Tutorial How to Add Chamfer Dimension In Solidworks Drawing

Dimensioning standards

How to interpret the values of a chamfer and a thread in a blueprint

Solved Multiple chamfers on drawings PTC Community

Inventor Ability to change the decimal places in the call out of the

Threads Are The Major Geometrical Shapes Of Screws And Screw Holes.

Click Chamfer Dimension On The Dimensions/Relations Toolbar Or Click Tools > Dimensions > Chamfer.

Web Basic Dimensioning Introduction Dimensioning Refers To The Addition Of Size Values To Drawing Entities.

Web Since Threading Often Produces Starting Burrs, These Can Be Minimized By Specifying A 45° Countersink Or Chamfer Which Is.015″ Minimum Larger Than The Major Diameter On Internal Threads (See Figure 4) And.015″ Minimum Smaller Than The Minor Diameter On External Threads (See Figure 3).

Related Post: