Deep Drawing Manufacturing

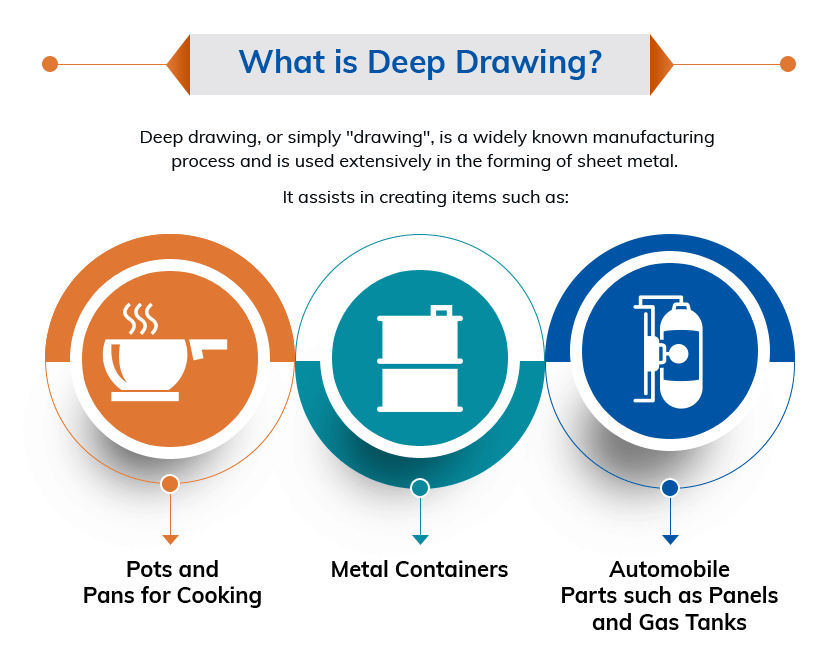

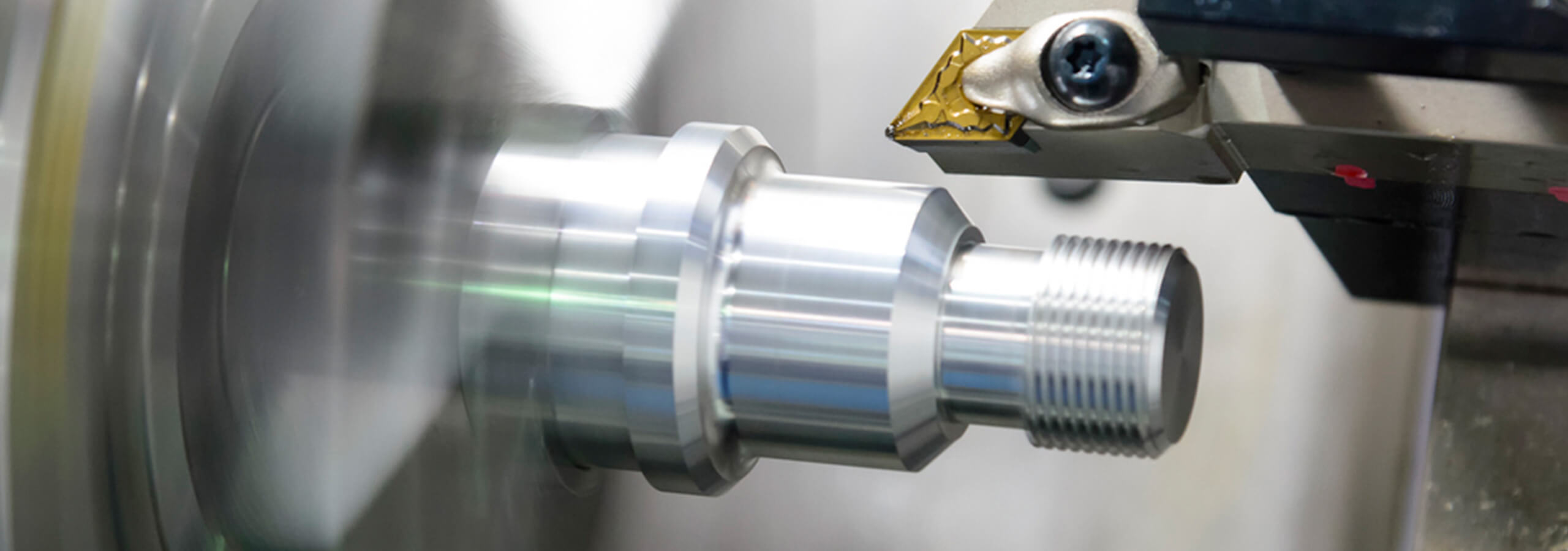

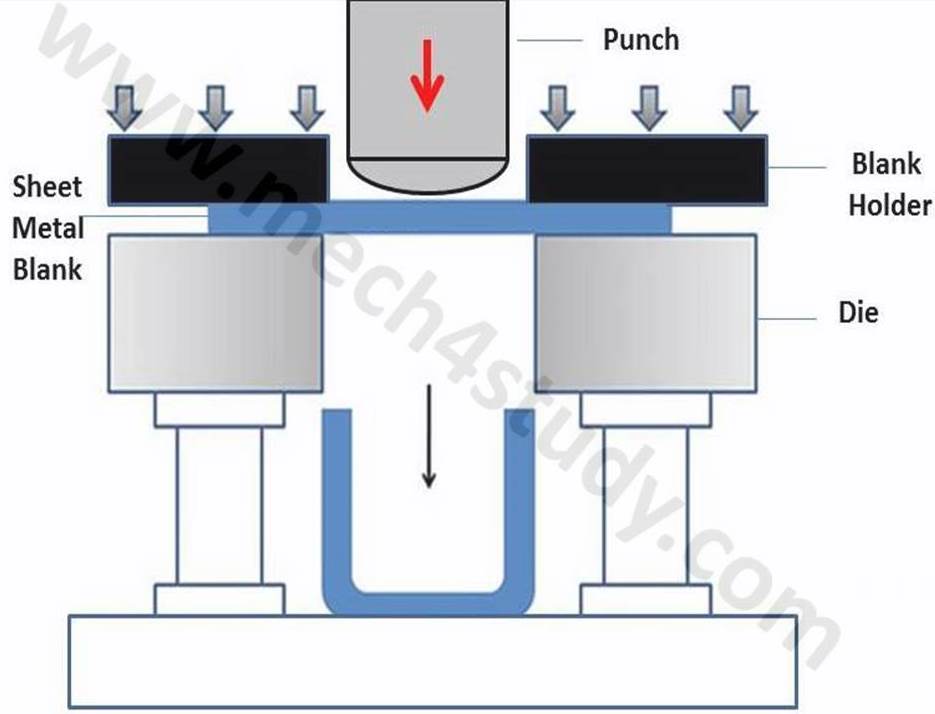

Deep Drawing Manufacturing - The process is considered deep drawing when the depth of the drawn part exceeds its diameter. Today the company has manufacturing facilities offering production services and tooling in the us and europe and provides process development and equipment from its us headquarters in phoenix az. Deep drawn parts are created from a single sheet of metal rapid cycle times: Web deep drawing is one of the most common methods in sheet metal forming and is highly valuable for large quantities or long run production orders. At jingjiang, we employ the following design methods: It assists in creating items such as pots and pans for cooking, containers, and automobile parts like panels and gas tanks. 3] if the ratio of height to diameter of the product is greater than 0.5 then this drawing operation is known as deep drawing. Web specialists in deep drawing, deep draw metal stamping & deep drawn enclosures. [1] it is thus a shape transformation process with material retention. Web what is deep drawn manufacturing? Starting out with only two presses, pat thompson built the company on a simple premise: 2] it is combination of metal forming process & sheet metal process. Prospect machine products deep draw metal stamping. Since that time, much has been published regarding deep drawing dies and processes, but very little can be found regarding its origin. Web deep drawing is. Defects, both in shape and location, are dimensionally deviant and constitute a significant difficulty for companies that produce large quantities of their products. Web deep drawing is a sheet metal forming process in which a sheet metal blank is radially drawn into a forming die by the mechanical action of a punch. Web hytech engineers utilized their prior experience to. It assists in creating items such as pots and pans for cooking, containers, and automobile parts like panels and gas tanks. Starting out with only two presses, pat thompson built the company on a simple premise: Fea (finite element analysis) for deep drawn and diaphragm design; Web hudson technologies is a leading u.s. Mechanics of materials in modern manufacturing methods. Manufacturer of deep drawn metal enclosures, or cases, and stampings, including metal diaphragms. Pots and pans for cooking, containers, sinks, automobile parts, such as panels and gas tanks, are among a few of the items manufactured by sheet metal deep drawing. Web specialists in deep drawing, deep draw metal stamping & deep drawn enclosures. Web hytech engineers utilized their prior. Web the deep drawing manufacturing process can produce various shapes of deep drawn parts. Web deep drawing is the most difficult procedure in manufacturing to obtain a faultless result. The mechanical action of the punch in combination with the hollow die applies both tensile and compressive forces. Web hudson technologies is a leading u.s. 2] it is combination of metal. H dp ≥ 0.5 h d p ≥ 0.5 Prospect machine products deep draw metal stamping. Deep drawing, or simply drawing, is a widely known manufacturing process and is used extensively in the forming of sheet metal. Deep drawing is a manufacturing process that involves the use of a punch and die to form a sheet metal into a desired. The process can be applied to a variety of industries and is associated with lower cost raw. We have the capabilities for deep drawn metal stamping, progressive die stamping, prototyping and more. Web what is deep drawn manufacturing? Web headquartered in valley city, oh, boehm pressed steel co. Web hudson technologies is a leading u.s. Web deep drawing is the most difficult procedure in manufacturing to obtain a faultless result. Since that time, much has been published regarding deep drawing dies and processes, but very little can be found regarding its origin. Web deep drawing may be a viable production solution for any manufacturing process that requires one or more of the following: Fea (finite. The process is considered deep drawing when the depth of the drawn part exceeds its diameter. Web deep drawing is the most difficult procedure in manufacturing to obtain a faultless result. Web deep drawing is one of the most common methods in sheet metal forming and is highly valuable for large quantities or long run production orders. Serving global customers. Large quantities of products are easily manufactured through deep drawing The process can be applied to a variety of industries and is associated with lower cost raw. Web welcome to our deep draw shop. Web deep drawing is the process of forming sheet metal by using a punch to radially draw the metal into a forming die. It assists in. Web deep drawing may be a viable production solution for any manufacturing process that requires one or more of the following: Web headquartered in valley city, oh, boehm pressed steel co. Web deep drawing is the process of forming sheet metal by using a punch to radially draw the metal into a forming die. Manufacturer of deep drawn metal enclosures, or cases, and stampings, including metal diaphragms. Defects, both in shape and location, are dimensionally deviant and constitute a significant difficulty for companies that produce large quantities of their products. Since that time, much has been published regarding deep drawing dies and processes, but very little can be found regarding its origin. Fea (finite element analysis) for deep drawn and diaphragm design; The mechanical action of the punch in combination with the hollow die applies both tensile and compressive forces. Deep drawn parts are created from a single sheet of metal rapid cycle times: Web deep drawing is one of the most common methods in sheet metal forming and is highly valuable for large quantities or long run production orders. 3] if the ratio of height to diameter of the product is greater than 0.5 then this drawing operation is known as deep drawing. [1] it is thus a shape transformation process with material retention. Deep drawing is a manufacturing process that involves the use of a punch and die to form a sheet metal into a desired shape. H dp ≥ 0.5 h d p ≥ 0.5 The process is considered deep drawing when the depth of the drawn part exceeds its diameter. Prospect machine products deep draw metal stamping.

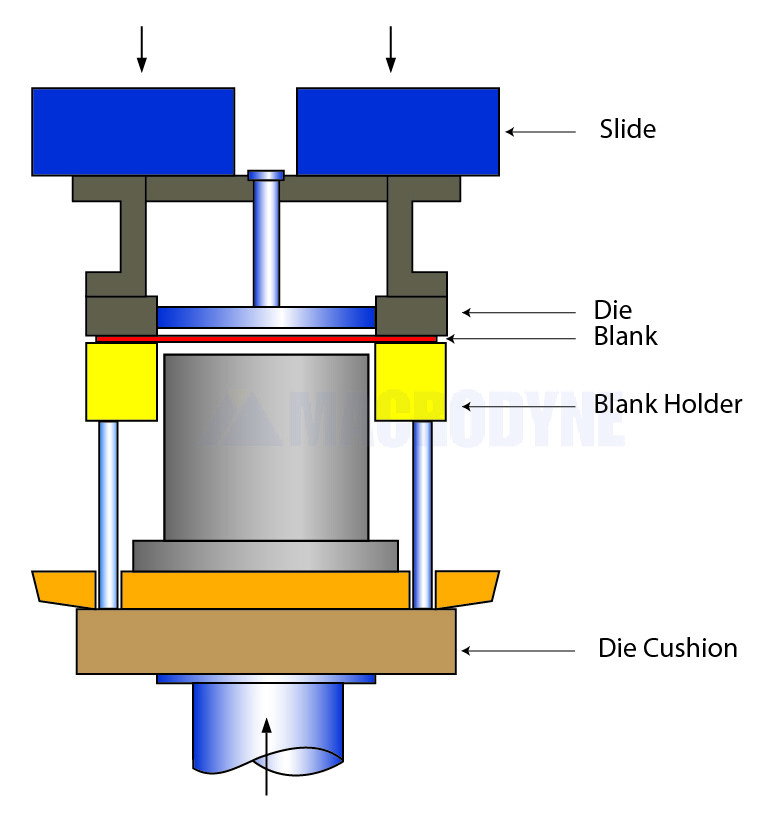

Deep Drawing 101 Macrodyne

What Is Involved in the Deep Drawn Manufacturing Process? Hudson

Deepdrawn manufacturing process for MDI cans YouTube

Deep drawing of sheet metal

What Is Deep Drawing ? Working Of Deep Drawing Sheet Metal Processes

DeepDrawn Process Our DeepDrawing Process

What is Deep Drawing Process? Mech4study

What is Deep Drawing? Process, Diagram, Advantages & Applications

LESSONS LEARNED DEEP DRAW STAMPING Duggan Manufacturing

What is Deep Drawing Process? Mech4study

Starting Out With Only Two Presses, Pat Thompson Built The Company On A Simple Premise:

Web Deep Drawing Is A Manufacturing Process That Is Used Extensively In The Forming Of Sheet Metal Into Cup Or Box Like Structures.

At Jingjiang, We Employ The Following Design Methods:

Web Specialists In Deep Drawing, Deep Draw Metal Stamping & Deep Drawn Enclosures.

Related Post: