Deep Drawing Operation

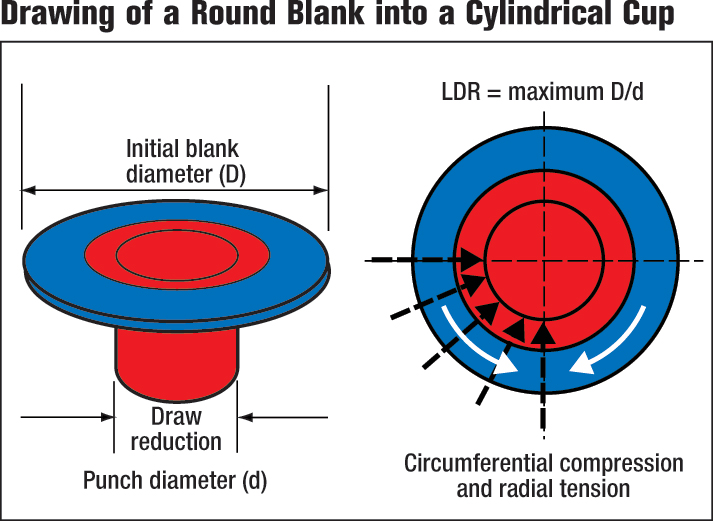

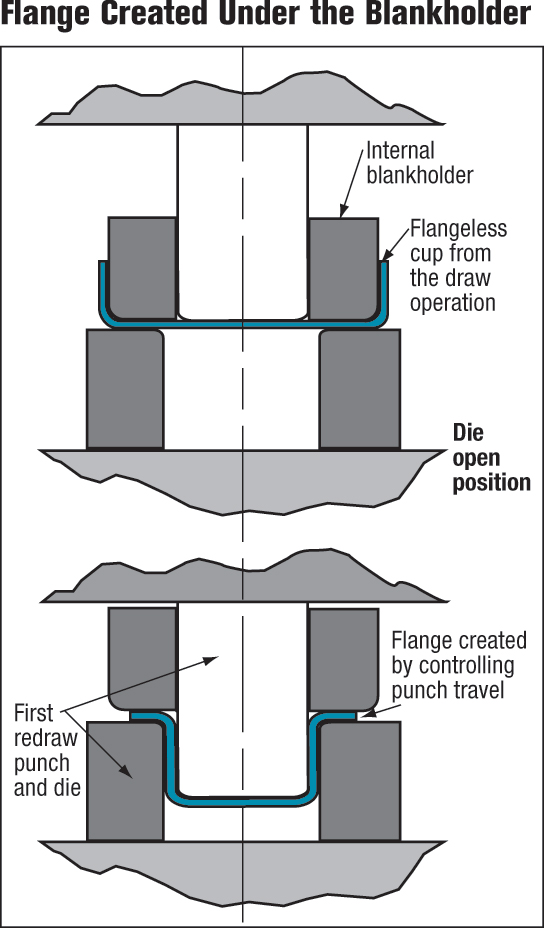

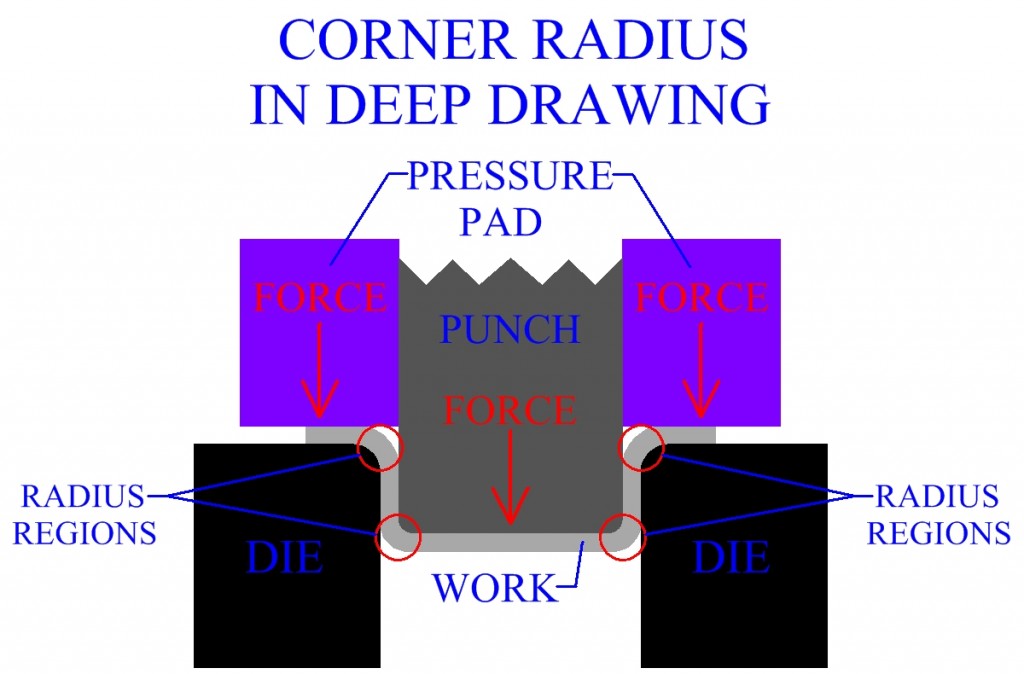

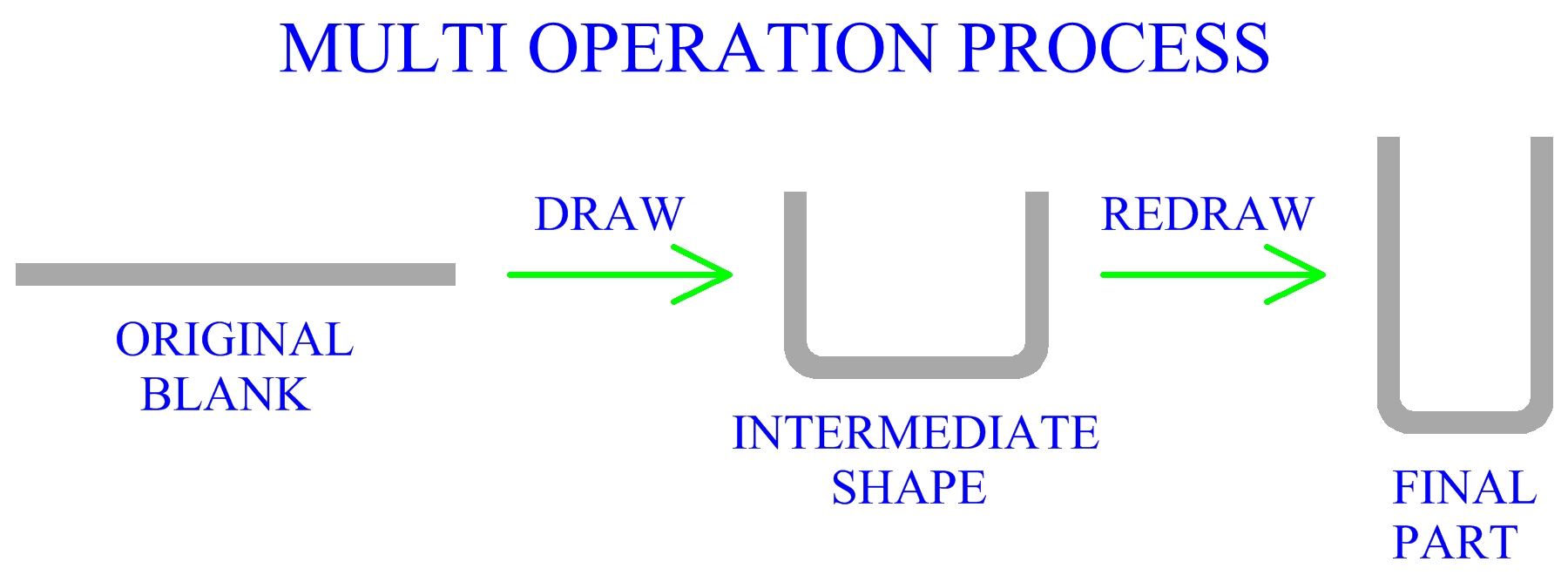

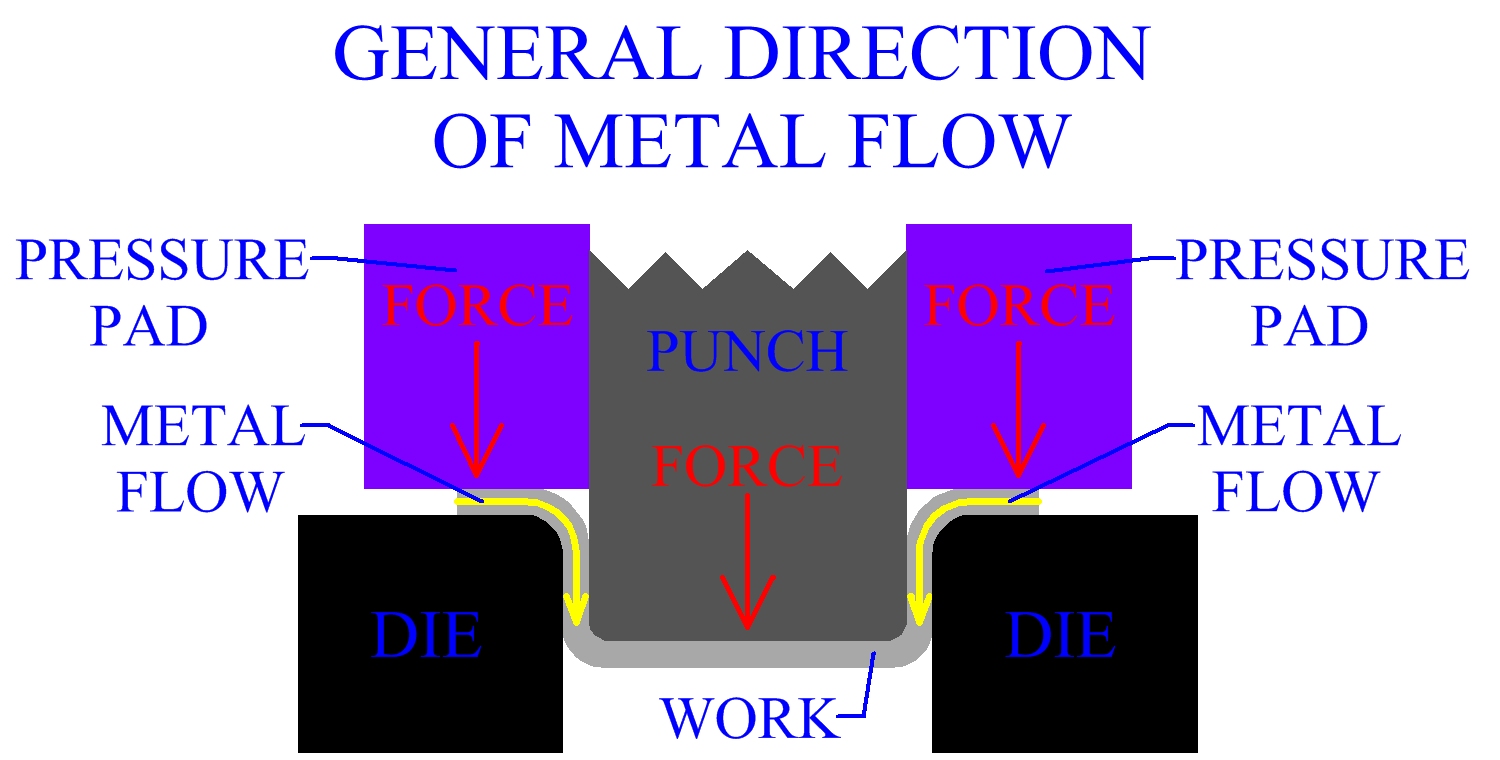

Deep Drawing Operation - Web process, diagram, advantages & applications. Deep drawing load and its components and their variations with punch movement. Now, with further increase of the load, the bent part of the blank is straightened in order to. Compressive and tensile forces are used in the deep drawing operation to convert a. The mold for deep drawing is been called deep drawing die. It is a blank / piece of sheet metal which is placed. Web 1.1 deep drawing process. Sheet metal deep drawing calculations. Many cylindrical parts like metal can, pots, container for food and beverages, kitchen sinks, automobile fuel. The shape of product depends upon shape of punch. Initially, the blank is heated to plastic state and. Web mechanics of deep drawing: Web introduction deep drawing is a forming procedure in which sheet metals are pressed into a die cavity and establish into a desired shape. Web pdf | on may 13, 2023, araveeti c s reddy published introduction to deep drawing | find, read and cite all. Web introduction deep drawing is a forming procedure in which sheet metals are pressed into a die cavity and establish into a desired shape. It is a blank / piece of sheet metal which is placed. It is a versatile tool that can produce a wide range of products, including cooking pots, pans, automotive parts, and electrical enclosures. (bandyopadhyay and. Web however, regardless of the many factors involved, the most important element to a successful deep drawing operation is initiating metal flow. Types of deep drawing parts As the application of load starts, the blank is first bent onto the round edge of the die cavity. Web mechanics of deep drawing: Now, with further increase of the load, the bent. The basics deep drawing produces a part from a flat blank via the action of a punch force onto the blank. When compared to other metal forming methods, deep drawing has a wide range of applications. Pots and pans for cooking, containers, sinks, automobile parts, such as panels and gas tanks, are among a few of the items manufactured by. Pots and pans for cooking, containers, sinks, automobile parts, such as panels and gas tanks, are among a few of the items manufactured by sheet metal deep drawing. Web however, regardless of the many factors involved, the most important element to a successful deep drawing operation is initiating metal flow. Material is displaced to create a larger, or smaller, diameter. Web process, diagram, advantages & applications. Web 1.1 deep drawing process. The basics deep drawing produces a part from a flat blank via the action of a punch force onto the blank. It is a blank / piece of sheet metal which is placed. Web the deep drawing process basically can be divided into three different kinds of load application. Specifically, if the depth of the item created is equal to or greater than its radius, then the metal forming process. Web introduction deep drawing is a forming procedure in which sheet metals are pressed into a die cavity and establish into a desired shape. Many cylindrical parts like metal can, pots, container for food and beverages, kitchen sinks, automobile. Web 1.1 deep drawing process. The shape of product depends upon shape of punch. Mhdd is a kind of sheet hydroforming method in which a. Now, with further increase of the load, the bent part of the blank is straightened in order to. As the application of load starts, the blank is first bent onto the round edge of the. In the bulging process a. The mold for deep drawing is been called deep drawing die. When compared to other metal forming. Web deep drawing operation in sheet metal sheet metal deep drawing process. It is a blank / piece of sheet metal which is placed. Web 1.1 deep drawing process. Properties of work metal for optimal formability. Web these other forming methods include: The metal thickness, the metal type, and the blank size. The basics deep drawing produces a part from a flat blank via the action of a punch force onto the blank. Pots and pans for cooking, containers, sinks, automobile parts, such as panels and gas tanks, are among a few of the items manufactured by sheet metal deep drawing. Web mechanics of deep drawing: When compared to other metal forming. Sheet metal deep drawing calculations. To the trained eye, the finished product can tell a very clear story about the quality of the process. Properties of work metal for optimal formability. (bandyopadhyay and panda, 2014 ). Web 1.1 deep drawing process. Web deep drawing is a process of converting metal sheet into cylindrical or box shaped structure with or without changing its length and thickness. The metal thickness, the metal type, and the blank size. Web deep drawing is a processing method that uses a drawing die to press the flat blank into various open hollow parts or process the manufactured hollow parts into other shapes of hollow parts under the pressure of a press. Web the act of forcing metal into a given shape introduces a host of possible problems and concerns. Web deep drawing is a manufacturing process that is used extensively in the forming of sheet metal into cup or box like structures. The basics deep drawing produces a part from a flat blank via the action of a punch force onto the blank. Derivation of mathematical expression for load and its comparison with sachs relation. The shape of product depends upon shape of punch.

Deep Drawing from A to Z MetalForming Magazine Article

Deep drawing operation sheet metal operation (part4) Tamil

Deep Drawing from A to Z MetalForming Magazine Article

Deep Drawing Of Sheet Metal TheMech.in

Deep drawing of sheet metal

Deep Drawing Of Sheet Metal

What Is Deep Drawing ? Working Of Deep Drawing Sheet Metal Processes

Deep Drawing Of Sheet Metal

Deep Drawing Of Sheet Metal

Deep Drawing Of Sheet Metal

It Is A Blank / Piece Of Sheet Metal Which Is Placed.

Following Calculations Are Required During The Design And Manufacturing Of.

Initially, The Blank Is Heated To Plastic State And.

Now, With Further Increase Of The Load, The Bent Part Of The Blank Is Straightened In Order To.

Related Post: