Deep Drawing Part

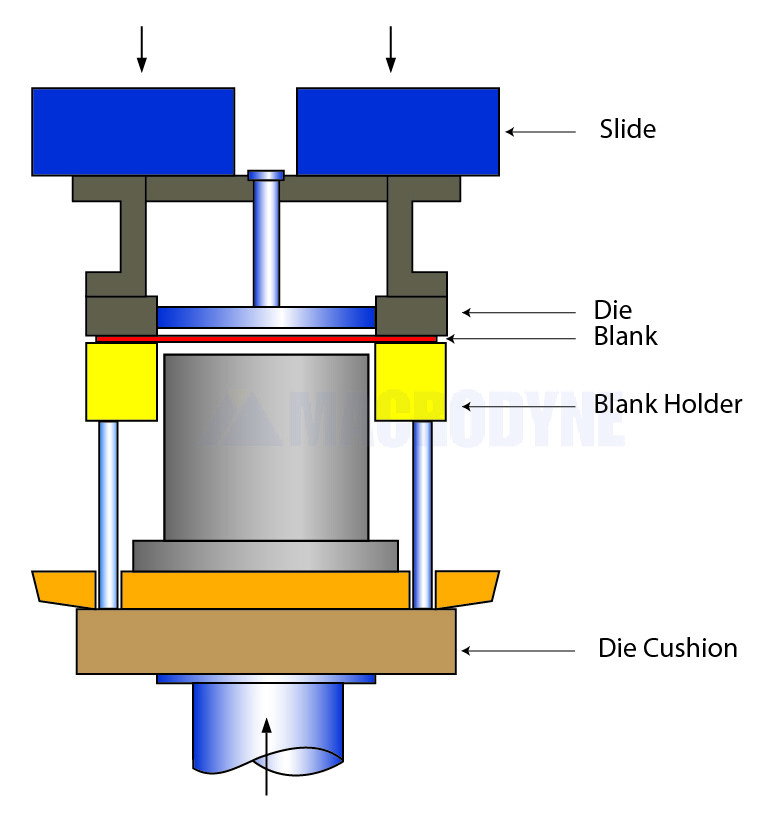

Deep Drawing Part - In essence, the biggest difference is the fact that with machining material is removed and with deep drawing material is deformed. Web a deep drawn part can be recognized by its depth and its smooth, radiused corners. Web deep drawing is a special process in sheet metal forming which is capable of forming many metallic parts and structures, and it covers a wide range of applications in packaging, automotive and aerospace industries. In diameter and 1 in. The mold for deep drawing is been called deep drawing die. The sheet metal is placed between two dies, and the punch is forced against it to create the desired profile. Successful deep drawing depends on many factors. This process is the combination of metal forming process and sheet metal process. Deep drawing punch, draw ring or die or matrice, and a blank holder. This means that stampings can be processed in less time than deep drawn components, which can significantly reduce costs. If the ratio of height to diameter of the product is greater than 0.5 then this drawing operation is known as. Web may 30, 2001 article bending and forming figure 1: Web though deep drawing is similar to metal stamping, the terms are not interchangeable. Web what is deep drawing? Web the deep drawing tool ever consists of three major. The sheet metal, or metal blank, is placed on the die and secured. Web what is deep drawing? Web the deep drawing tool ever consists of three major components: 2 fundamentals of deep drawing during the first draw. Web deep drawing is a useful process in aerospace engineering. In essence, the biggest difference is the fact that with machining material is removed and with deep drawing material is deformed. Deep drawing is the process of converting a blank of sheet metal into a cylindrical container with a flat or hemispherical base. Simple parts can be drawn to their finished shape in a single step while complex shapes, including. Web deep drawing is a sheet metal forming process in which a sheet metal blank is radially drawn into a forming die by the mechanical action of a punch. Web in contrast, deep drawn part forming can comprise many steps that include die design, material preparation, blanking, drawing, trimming, and inspection. Tall, you are not making a. Stamping does not. Drawn parts are seamless, giving them impressive strength and durability lower unit production cost, particularly with higher runs reduced tooling costs while it’s ideal for cylindrical. 2 fundamentals of deep drawing during the first draw. Web deep drawing can be defined as a process used to create a part with a height that is two or more times its minimum. Drawn parts are seamless, giving them impressive strength and durability lower unit production cost, particularly with higher runs reduced tooling costs while it’s ideal for cylindrical. The process is repeated until the component achieves the desired size and shape. This information can prove invaluable during both the concept and design phase of the project, and can ensure the right outcome. This information can prove invaluable during both the concept and design phase of the project, and can ensure the right outcome the first time. Tall, you are not making a. Process o annual production volume o target production rates o target pricing o finished part shape and tolerances o forming progression and number of stages Web may 30, 2001 article. Web deep drawing is a sheet metal forming process in which a sheet metal blank is radially drawn into a forming die by the mechanical action of a punch. Web the deep drawing tool ever consists of three major components: Deep drawing is the process of converting a blank of sheet metal into a cylindrical container with a flat or. In essence, the biggest difference is the fact that with machining material is removed and with deep drawing material is deformed. Types of deep drawing parts. Successful deep drawing depends on many factors. Web what is deep drawing? Web deep drawing (in the context of sheet metal forming) is the process by which a flat sheet of steel is transformed. Tall, you are not making a. This means that stampings can be processed in less time than deep drawn components, which can significantly reduce costs. Successful deep drawing depends on many factors. Web deep drawing belongs to sheet metal techniques like bending, cutting, hydroforming, roll forming, spinning, stretching and stamping fabrication differences between deep drawing and machining. Stamping does not. Web deep draw stainless steel sink process considerations when it comes time to design a deep drawn part, the following considerations should be taken into account: In diameter and 1 in. Web deep drawing belongs to sheet metal techniques like bending, cutting, hydroforming, roll forming, spinning, stretching and stamping fabrication differences between deep drawing and machining. The process is repeated until the component achieves the desired size and shape. Simple parts can be drawn to their finished shape in a single step while complex shapes, including parts that are especially deep, may require. 2 fundamentals of deep drawing during the first draw This means that stampings can be processed in less time than deep drawn components, which can significantly reduce costs. The sheet metal is placed between two dies, and the punch is forced against it to create the desired profile. Process o annual production volume o target production rates o target pricing o finished part shape and tolerances o forming progression and number of stages Web deep drawing is a sheet metal forming process in which a sheet metal blank is radially drawn into a forming die by the mechanical action of a punch. Web deep drawing is a processing method that uses a drawing die to press the flat blank into various open hollow parts or process the manufactured hollow parts into other shapes of hollow parts under the pressure of a press. Deep drawing punch, draw ring or die or matrice, and a blank holder. Web the size ratio of each part of the deep drawing piece should be appropriate. Web deep drawing is a sheet metal forming process that uses a punch and dies to draw (pull) the workpiece into the desired shape. In general, deep drawing is used to fabricate parts and products that are deeper than metal stamping can accommodate. Web may 30, 2001 article bending and forming figure 1:

304 stainless steel deep drawing shellstainless,steel,deep,drawing

High Precision Deep Drawing Die Stainless Steel Q235 304 201 Stamping Parts

best deep drawing process, by chris YouTube

Steel deep drawing parts Metal parts manufacturer

Deep Drawing 101 Macrodyne

Deep Draw Metal Stampings & Formed Parts Hudson Technologies

Deep Drawing of Sheet Metal Stoeckli Metall AG Metalworking Center

Deep drawing of sheet metal

Deep Draw Process for Precision Metal Components TransMatic TransMatic

Deep Drawing New England Metalform, Inc., Precision Metal Stamped

Examples Range From Cans, Pots, Kegs, And Compressed Gas Cylinders To Eyelets, Sinks, And Automotive Body Panels.

The Sheet Metal, Or Metal Blank, Is Placed On The Die And Secured.

The Outline Of The Flanges Of The Drawing Parts Should Be.

Web What Is Deep Drawing?

Related Post: