Rotary Draw Bending

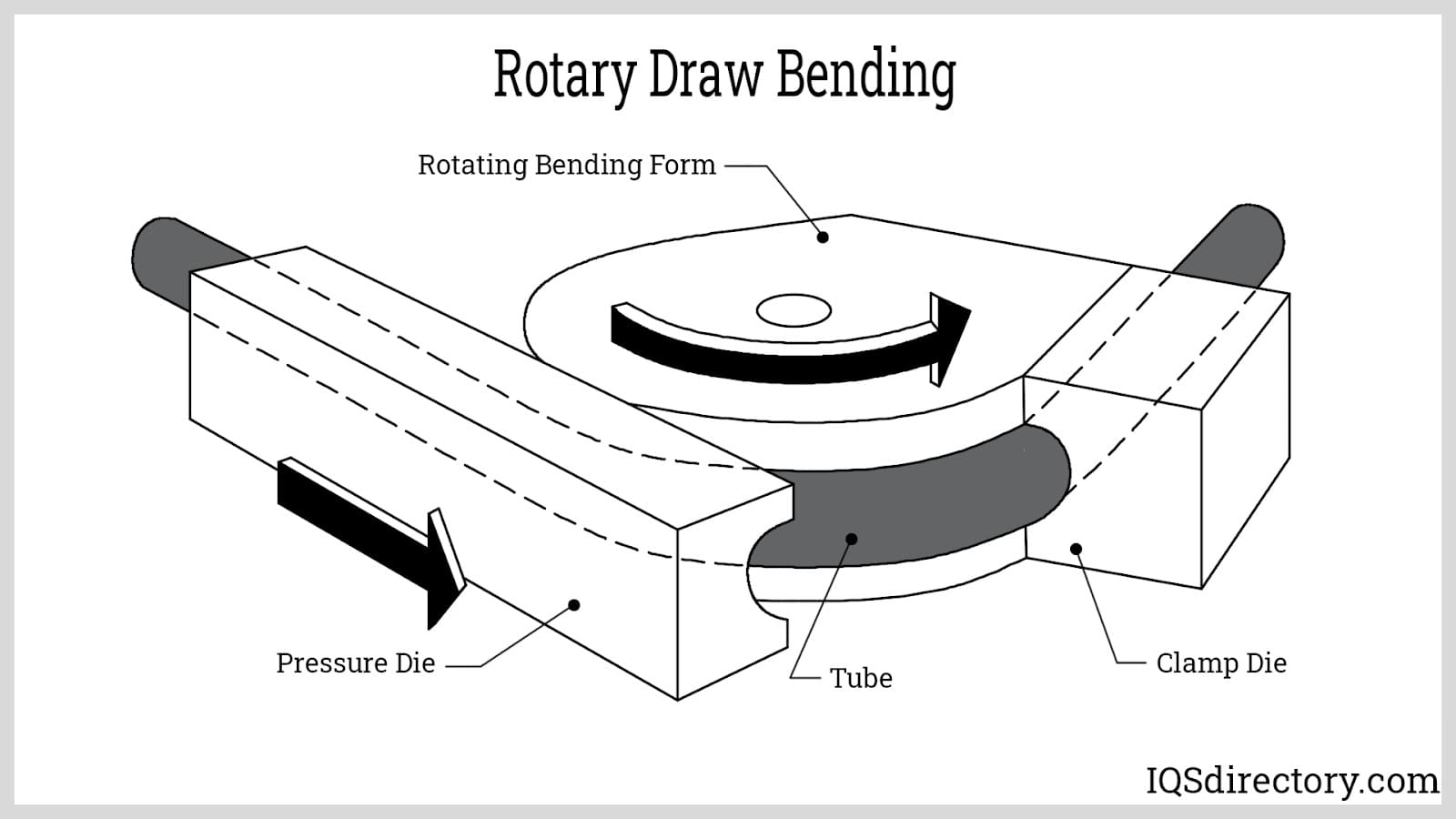

Rotary Draw Bending - Features pictures of rotary draw benders, bent material ready for shipment and related. An engineer’s guide to bending tubes may 14, 2016 • 5 likes • 5,565 views download now download to read offline engineering this guide is an excellent starting point for anyone who has questions or is interested in learning about bending tooling. One, you need a bend die. Over the years, efforts have been in progress to identify the process parameters of rdb process so that the quality of the bent portions of metal tubes can be improved. Also shown is plastic deformation in tube bending and the effect of tools’ parameters. Web rotary draw bending (rdb) is one of the most commonly used bending processes for metal tubes in present era. Web principles of rotary draw bending bending forces as a tube or pipe is being bent, the outer wall at the point of the bend begins to stretch and thin out. Rotary draw bending (rdb) is a precise technology, since it bends using tooling or die sets which. Web rotary draw bending is a very accurate style of bending tube, pipe, solids, and more. The outside wall of the tube collapses and thins out, and the inside of the tube compresses and wrinkles. The minimum tool requirements for rotary draw bending are the bend die (around which the tube is bent), clamp die (which holds the tube in place as it bends around the bend die). A clamp die, which clamps the tube to the bend die; Over the years, efforts have been in progress to identify the process parameters of rdb process. The minimum tool requirements for rotary draw bending are the bend die (around which the tube is bent), clamp die (which holds the tube in place as it bends around the bend die). Web the basics when a tube is bent, basically two things happen. Rotary draw benders creates precise bends when the right tooling is matched to the application.. Web the rotary draw bending process for steel and other metals is explained by john rogers from kubes steel. Web rotary draw benders are the most popular machines for use in bending tube and pipe. More specifically, it’s the distance between two tangent point s, where a straight section begins to curve and the bend starts or finishes. A pressure. One, you need a bend die. Web the rotary draw bending process for steel and other metals is explained by john rogers from kubes steel. We describe four simple steps for setting up a complete set of tools on a machine, which if executed precisely and in the correct order, will maximize bend quality, tool life, and process control. 7.32,. The minimum tool requirements for rotary draw bending are the bend die (around which the tube is bent), clamp die (which holds the tube in place as it bends around the bend die). Web among these, rotary draw bending (rdb) presents the highest accuracy and repeatability even with bends having narrow bending radii [ 4 ], and, in the last. Web the distance between bends (dbb) is just what it says. Web rotary draw bending (rdb) is one of the most commonly used bending processes for metal tubes in present era. Rotary draw bending often employs an internal supporting mandrel and a wiper die to prevent wrinkling on the inside wall of a tight bend. Web rotary draw bending is. Web rotary draw benders are the most popular machines for use in bending tube and pipe. Web rotary draw bending (rdb) is one of the most commonly used bending processes for metal tubes in present era. More specifically, it’s the distance between two tangent point s, where a straight section begins to curve and the bend starts or finishes. Like. The outside wall of the tube collapses and thins out, and the inside of the tube compresses and wrinkles. Web the rotary draw bending process, as shown in fig. Specific tooling is required for each member size, shape and bend radius; 7.32, is generally used for bending aluminum and magnesium tubes. Common applications for rotary draw benders are handrails, frames,. Web the basics when a tube is bent, basically two things happen. Web one of the most common modes of bending is rotary draw bending. The rotary draw pipe bending technique is slower than other methods but has significantly fewer limitations. Simultaneously, the corresponding inner wall of the workpiece becomes thicker and more compressed. Web this article discusses several aspects. Web the rotary draw bending process for steel and other metals is explained by john rogers from kubes steel. Web the distance between bends (dbb) is just what it says. Like in press brake forming, tubes experience springback after bending, producing a bend that undergoes radial growth. Web a basic tooling setup on a rotary draw bender includes a bend. It forms the tube to the specified bend. Web rotary draw bending (rdb) is one of the most commonly used bending processes for metal tubes in present era. Web principles of rotary draw bending bending forces as a tube or pipe is being bent, the outer wall at the point of the bend begins to stretch and thin out. Web rotary draw bending is a very accurate style of bending tube, pipe, solids, and more. Web intro to rotary draw bending: The minimum tool requirements for rotary draw bending are the bend die (around which the tube is bent), clamp die (which holds the tube in place as it bends around the bend die). Therefore, this method is best suited for projects requiring many identical bends. Web the rotary draw bending process, as shown in fig. Press bending is probably the first bending process used on cold pipes and tubing. A pressure die, which applies pressure to the outer surface; Web rotary draw tube bending is a popular and versatile method of bending metal tubes and pipes that allows varying degrees of bending while maintaining a constant centerline radius (clr). Web the rotary draw bending process for steel and other metals is explained by john rogers from kubes steel. We describe four simple steps for setting up a complete set of tools on a machine, which if executed precisely and in the correct order, will maximize bend quality, tool life, and process control. Three pieces of tooling are needed. Web the distance between bends (dbb) is just what it says. The tube is held by the clamp and pressure die, and rotated around the bend die.

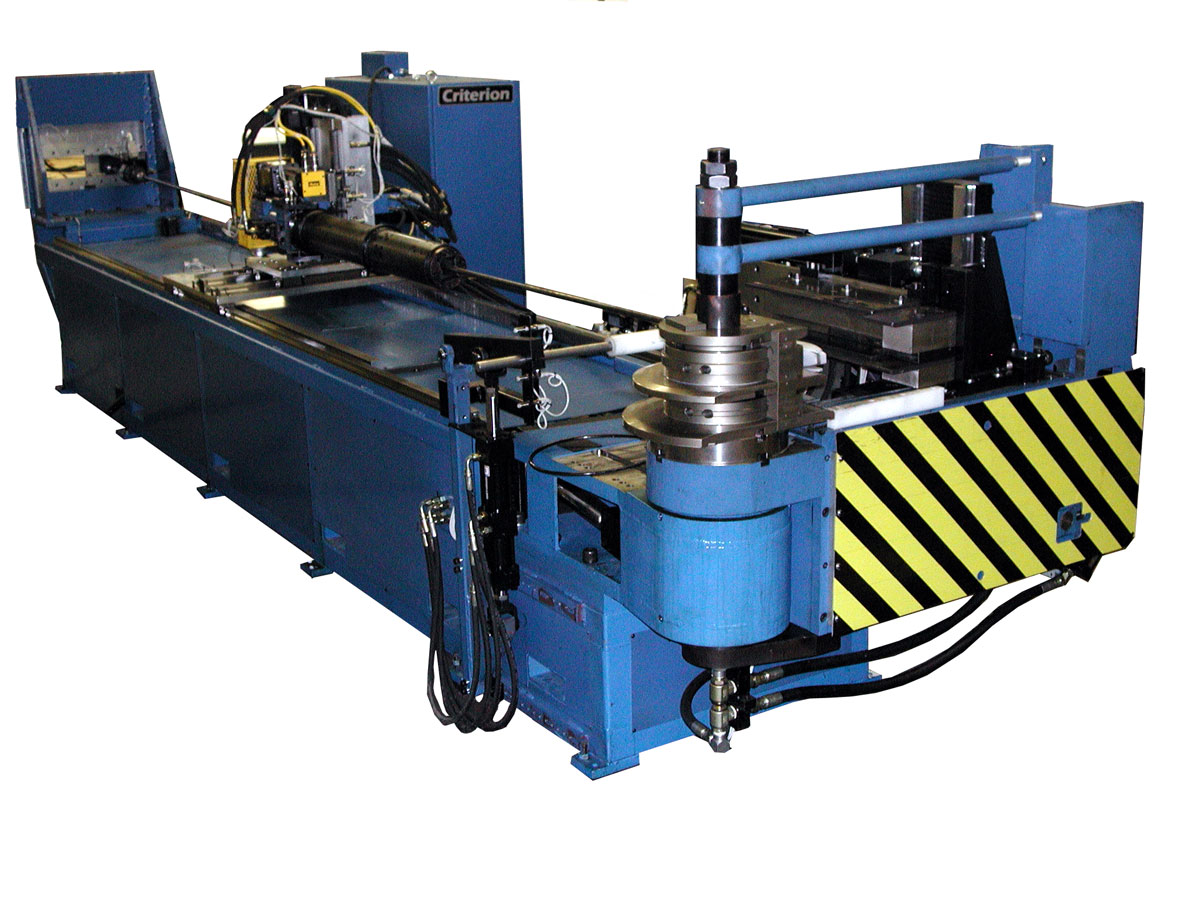

RotaryDraw TubeBending Machines, TubeFabricating Systems

Tube Bending What Is It? How Does It Work? Types Of

Baileigh 150AS Rotary Draw Bender

BM60 Rotary Draw Bending Machine Mackma machines in Australia

a and b Tools of the rotary draw bending process Borchmann et al. [2

Rotary Bending of Round Pipe YouTube

New Baileigh Rotary Draw Tube Bender

Rotary Draw Bending Kubes Steel YouTube

Rotary Draw & Compression Bending Albina Co., Inc.

RotaryDraw TubeBending Machines, TubeFabricating Systems

Also Shown Is Plastic Deformation In Tube Bending And The Effect Of Tools’ Parameters.

The Rotary Draw Pipe Bending Technique Is Slower Than Other Methods But Has Significantly Fewer Limitations.

This Type Of Bending Requires A Lot More Tooling Than Compression Bending.

It Is Typically Used To Bend A Tube Three To Four Times The Centerline Radius Of The Tube Diameter.

Related Post: