Sheet Metal Deep Drawing

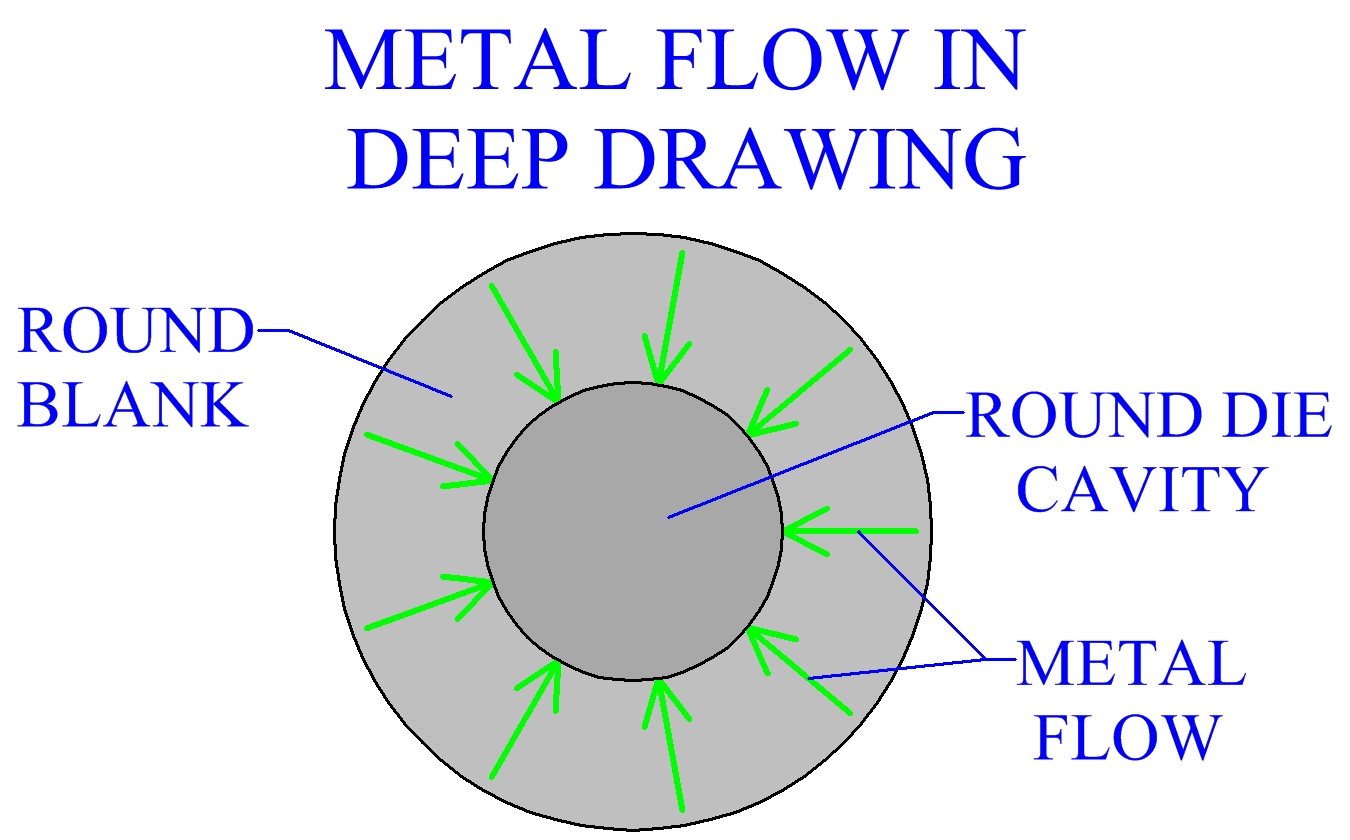

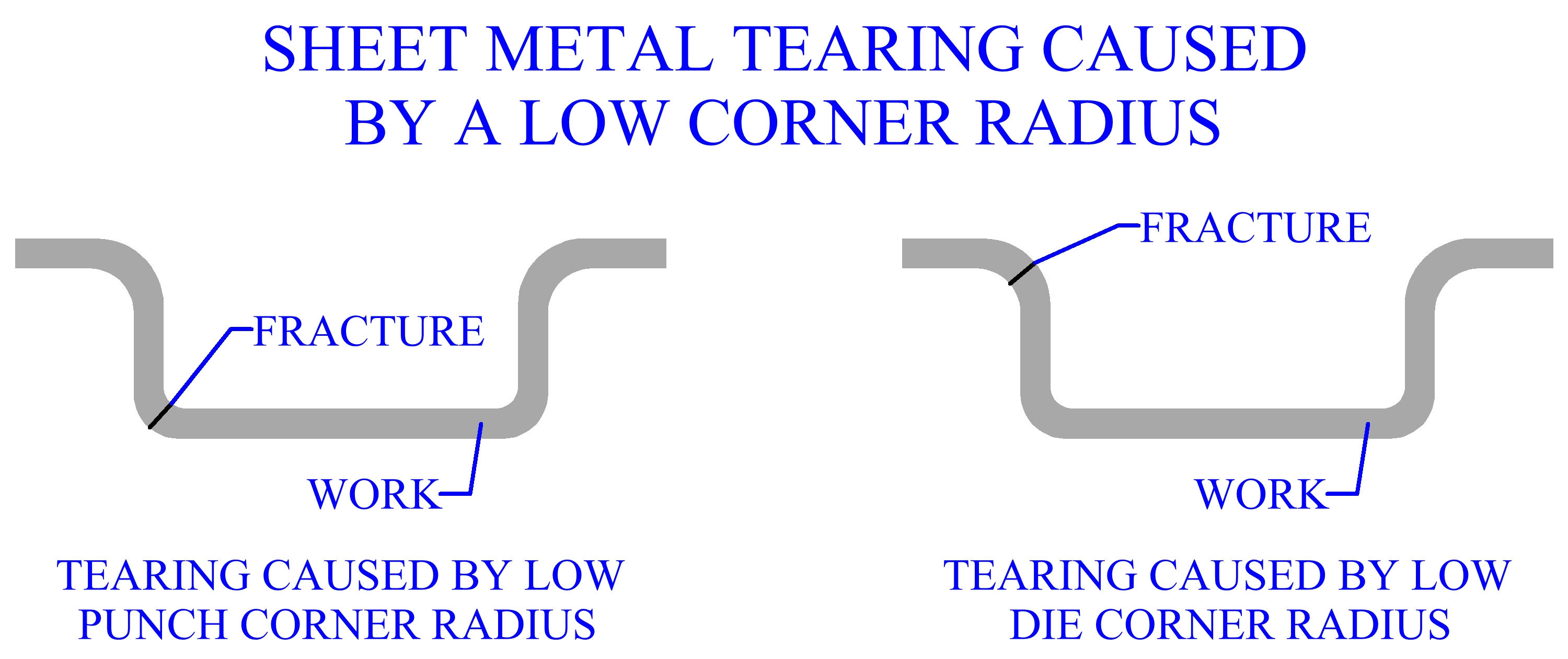

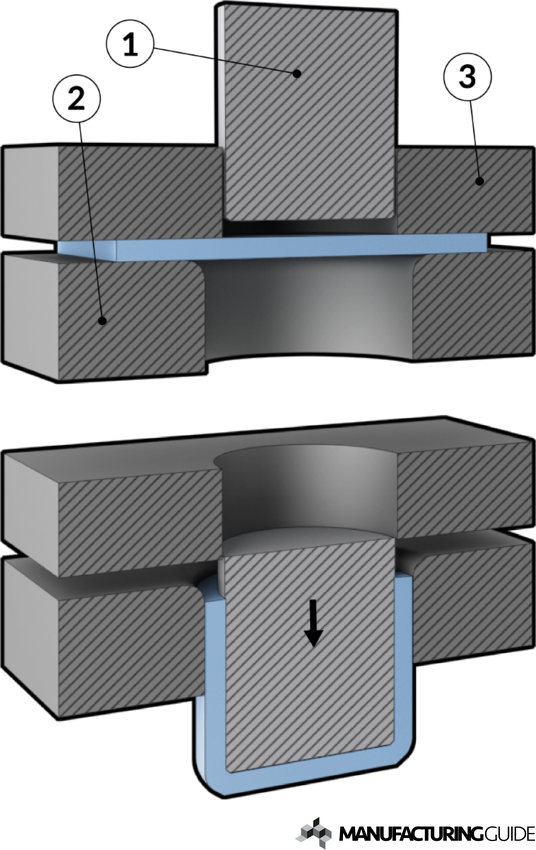

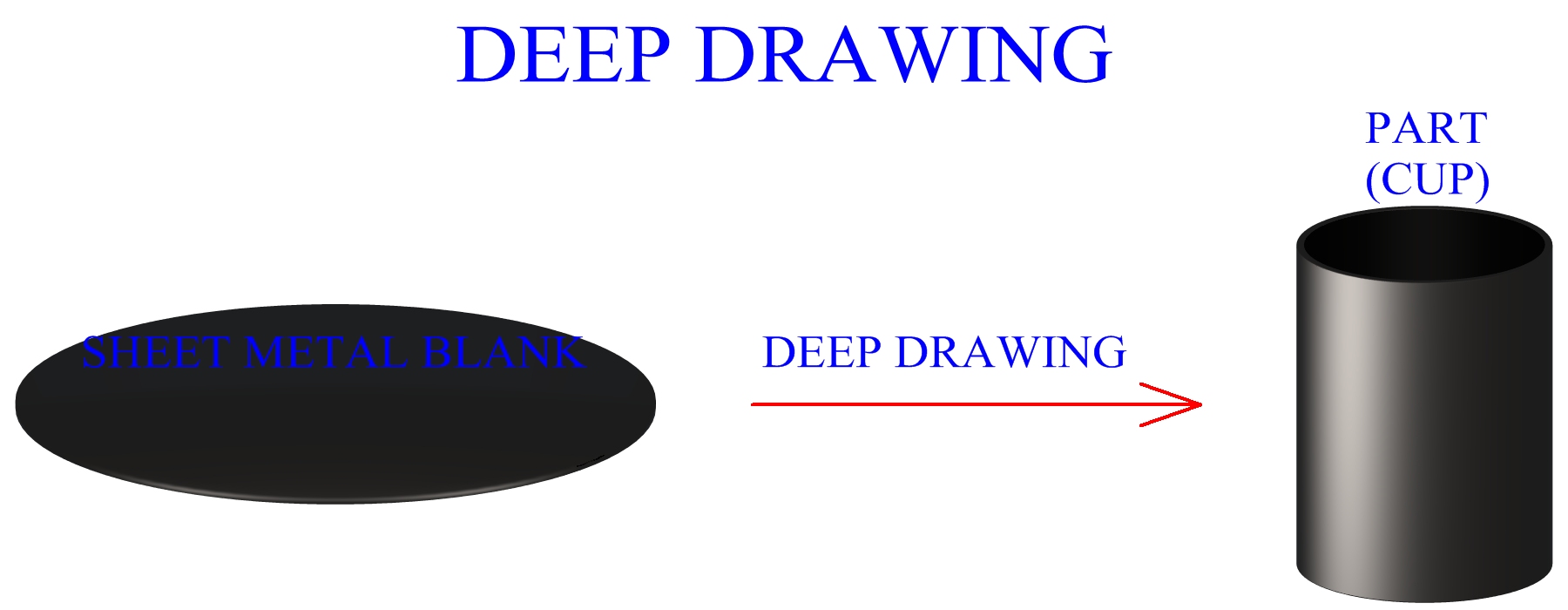

Sheet Metal Deep Drawing - Metal stamping can be used to form sheet metal into a variety of designs. Deep drawing is a process used to create hollow cylindrical shapes. To achieve a successful deep draw, it is crucial to consider factors such as material thickness, ductility, and friction between the sheet metal and the die. Web deep drawing is a sheet metal forming operation where sheet metal blank is drawn into hollow shapes by utilizing the combination of tensile and compressive forces. Learn how the process works, what typical challenges are, and what you need to consider when it comes to tooling. Web deep drawing is one of the most frequently used metal forming processes. Web according to din 8584, deep drawing is a tensile compression metal forming process, which shapes a sheet metal blank as a hollow body open on the one side or of a projected hollow body to one with a smaller cross section, without intentionally modifying its. What is deep drawing in sheet metal fabrication? The article summarizes the defects in drawing and factors considered in press selection for drawing. The process is considered deep drawing when the depth of the drawn part exceeds its diameter. This process uses a stamping die or series of dies to cut, pierce, and otherwise. The process is considered deep drawing when the depth of the drawn part exceeds its diameter. Learn how the process works, what typical challenges are, and what you need to consider when it comes to tooling. Web according to din 8584, deep drawing is a. It works by placing sheet metal over a die and pressing the metal blank into the die cavity using a punch, resulting in a hollow cylindrical shape with no reduction in the thickness of the sheet metal. Web according to din 8584, deep drawing is a tensile compression metal forming process, which shapes a sheet metal blank as a hollow. It works by placing sheet metal over a die and pressing the metal blank into the die cavity using a punch, resulting in a hollow cylindrical shape with no reduction in the thickness of the sheet metal. Deep drawing is a process used to create hollow cylindrical shapes. [1] it is thus a shape transformation process with material retention. This. The process is considered deep drawing when the depth of the drawn part exceeds its diameter. Web according to din 8584, deep drawing is a tensile compression metal forming process, which shapes a sheet metal blank as a hollow body open on the one side or of a projected hollow body to one with a smaller cross section, without intentionally. Web deep drawing is one of the most frequently used metal forming processes. This article illustrates the mechanics of the deep drawing of a cylindrical cup. [1] it is thus a shape transformation process with material retention. The article summarizes the defects in drawing and factors considered in press selection for drawing. It works by placing sheet metal over a. Metal stamping can be used to form sheet metal into a variety of designs. To achieve a successful deep draw, it is crucial to consider factors such as material thickness, ductility, and friction between the sheet metal and the die. Can deep drawing be used for all metals? Web according to din 8584, deep drawing is a tensile compression metal. Can deep drawing be used for all metals? This article illustrates the mechanics of the deep drawing of a cylindrical cup. Web deep drawing is a metal forming process for creating seamless, sheet metal parts that are closed on one end and have a depth greater than their radius. [1] it is thus a shape transformation process with material retention.. It works by placing sheet metal over a die and pressing the metal blank into the die cavity using a punch, resulting in a hollow cylindrical shape with no reduction in the thickness of the sheet metal. Web deep drawing is a sheet metal forming process in which a sheet metal blank is radially drawn into a forming die by. [1] it is thus a shape transformation process with material retention. What is deep drawing in sheet metal fabrication? This article illustrates the mechanics of the deep drawing of a cylindrical cup. Metal stamping can be used to form sheet metal into a variety of designs. Web deep drawing is a metal forming process for creating seamless, sheet metal parts. Web deep drawing is a sheet metal forming process in which a sheet metal blank is radially drawn into a forming die by the mechanical action of a punch. Deep drawing is a process used to create hollow cylindrical shapes. Web deep drawing is one of the most frequently used metal forming processes. To achieve a successful deep draw, it. The article summarizes the defects in drawing and factors considered in press selection for drawing. Web deep drawing is one of the most frequently used metal forming processes. Web deep drawing is a sheet metal forming operation where sheet metal blank is drawn into hollow shapes by utilizing the combination of tensile and compressive forces. Web deep drawing is a sheet metal forming process in which a sheet metal blank is radially drawn into a forming die by the mechanical action of a punch. Deep drawing is a process used to create hollow cylindrical shapes. Sheet metal is drawn in either hydraulic or mechanical presses. This article illustrates the mechanics of the deep drawing of a cylindrical cup. Metal stamping can be used to form sheet metal into a variety of designs. Can deep drawing be used for all metals? [1] it is thus a shape transformation process with material retention. To achieve a successful deep draw, it is crucial to consider factors such as material thickness, ductility, and friction between the sheet metal and the die. Web according to din 8584, deep drawing is a tensile compression metal forming process, which shapes a sheet metal blank as a hollow body open on the one side or of a projected hollow body to one with a smaller cross section, without intentionally modifying its. This process uses a stamping die or series of dies to cut, pierce, and otherwise. It discusses the fundamentals of drawing and drawability. What is deep drawing in sheet metal fabrication? The depth of the drawn parts often exceeds their diameter.

Deep Drawing Of Sheet Metal

Deep Drawing Of Sheet Metal

Deep drawing of sheet metal

Deep Drawing Of Sheet Metal

Deep Drawing Sheet Metal D&H Industries

What Is Deep Drawing ? Working Of Deep Drawing Sheet Metal Processes

Deep drawing Find suppliers, processes & material

Deep Drawing Of Sheet Metal

Deep Drawing of Sheet Metal Stoeckli Metall AG Metalworking Center

Deep Drawing Of Sheet Metal

Learn How The Process Works, What Typical Challenges Are, And What You Need To Consider When It Comes To Tooling.

Deep Drawing Is A Process Where Sheet Metal Is Radially Drawn Into A Forming Die, Producing A Deep, Hollow Shape Like Cans Or Caps.

It Finds Application In Various Industries But Is Best Known For Its Use In The Automotive Industry.

It Works By Placing Sheet Metal Over A Die And Pressing The Metal Blank Into The Die Cavity Using A Punch, Resulting In A Hollow Cylindrical Shape With No Reduction In The Thickness Of The Sheet Metal.

Related Post: