Wire Harness Drawing

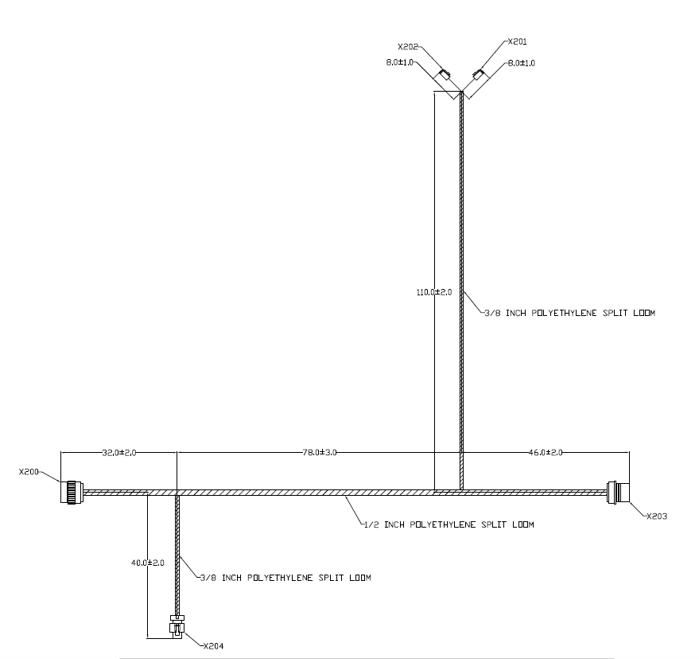

Wire Harness Drawing - Pay attention to which components are connected and the type of connection. The first step in reading a wiring harness drawing is to identify the component. Requirements and best practices include these general items. Web dimensioning and tolerancing cable/harness drawings follow standard ansi y14.5m 1994 practices. For oems and harness manufacturers, the comprehensive arcadia harness toolset allows capture, automation and a greatly reduced workload for engineering, purchase and service departments allowing you to seamlessly integrate into your existing process and workflow. Web wiring harnesses are used to connect electrical components within vehicles, and require a thorough understanding of electrical schematics and systems in order to interpret and troubleshoot them. Web a wiring harness drawing is a diagram that shows the pathways and connectors of the electrical system. Web the next step is to understand the relationship between the components. Web first, understand what a wire harness is, then we’ll discuss the steps involved in designing a wire harness. Whether you’re working on quick test articles or aerospace grade drawings, rapidharness will revolutionize the way you work. A wiring diagram view is an automated graphic composite of the active harness design project's wiring diagram. More detailed and accurate design with the use of preferred parts. At fusion design, our expert designers are capable of creating a wire harness accomplish the task at hand in the most economical means possible. L3 cable/harness drawings have evolved over time to. Purpose this is indeed basic, but it’s very necessary for designing the most reliable wire harness possible for your application. Twist the ends of the traveler wires around the two bare brass screw terminals. Arcadia wire harness design software helps electrical engineers create validated wiring diagrams, wire & cable harness layouts, formboards and manufacturing documentation quickly & accurately, like never. Purpose this is indeed basic, but it’s very necessary for designing the most reliable wire harness possible for your application. Pay attention to which components are connected and the type of connection. Connectors and their associated parts associated parts of splices associated parts of connection points crimps layout labels For example, a dotted line may indicate a direct connection. Web. We can help you with cable and wire harness design. Web considerations when drawing a wire harness environmental considerations. Once you know the symbols, you can begin to read the actual diagram. We’ll review components and materials, followed by a discussion of the options for purchasing wire harnesses. The appearance of the diagram is a typical representation of how the. Web transform the way you design, manufacture and collaborate. Web considerations when drawing a wire harness environmental considerations. L3 cable/harness drawings have evolved over time to meet the needs and requirements of l3 programs. Once you know the symbols, you can begin to read the actual diagram. Push the white neutral wires to the back of the switch box, then. If you choose to use your. Web wiring harnesses are used to connect electrical components within vehicles, and require a thorough understanding of electrical schematics and systems in order to interpret and troubleshoot them. Web creating a solid fabrication drawing for a wire harness or cable assembly is 100% key to having a successful and repeatable build. Tighten the screws. Web if regular service is needed, label both ends of each cable assembly in a way that aligns with wiring diagram labeling. Easy to use, allowing engineers to. Twist the ends of the traveler wires around the two bare brass screw terminals. Connectors and their associated parts associated parts of splices associated parts of connection points crimps layout labels Each. Automatic functionality makes placing, arranging, and dimensioning the harness and its segments easier. Web the best custom wiring harness manufacturer the custom wire harness is built according to the customer detailed specification and our professional standard. The first step in reading a wiring harness drawing is to identify the component. The cable harness drawing and design highly depend on several. We can help you with cable and wire harness design. Whether you’re working on quick test articles or aerospace grade drawings, rapidharness will revolutionize the way you work. It can be daunting to decipher the thousands of wires and connectors that are used in modern vehicles, but with the right information, it can be done. Easy to use, allowing engineers. Purpose this is indeed basic, but it’s very necessary for designing the most reliable wire harness possible for your application. The first step in reading a wiring harness drawing is to identify the component. Custom wiring harness capacity make prototypes according to your drawing or spec sheet. Web wirely is a wiring harness tool that allows the user to enter. Web an ideal wiring harness diagram will have symbolized components, optimum positioning, splice positions, and wire colours. For example, a dotted line may indicate a direct connection. Each step is monitored and goods will be strictly tested before each shipment. Custom wiring harness capacity make prototypes according to your drawing or spec sheet. Web e3.formboard is a complete solution for creating wiring harness drawings for manufacturing. The first step in reading a wiring harness drawing is to identify the component. It can be daunting to decipher the thousands of wires and connectors that are used in modern vehicles, but with the right information, it can be done. Pay attention to which components are connected and the type of connection. This wires the cable pinouts identically so the same pin or wire pairs connect straight through from one end to the other. Note the direction of each wire and the orientation of the components. Web dimensioning and tolerancing cable/harness drawings follow standard ansi y14.5m 1994 practices. Take some time to learn the symbols for items like resistors, capacitors, and transistors, as these will be used on almost all diagrams. Web first, understand what a wire harness is, then we’ll discuss the steps involved in designing a wire harness. Push the white neutral wires to the back of the switch box, then locate the the incoming black and red traveler wires. Web wiring harnesses are used to connect electrical components within vehicles, and require a thorough understanding of electrical schematics and systems in order to interpret and troubleshoot them. The appearance of the diagram is a typical representation of how the wire bundling will ultimately look like.

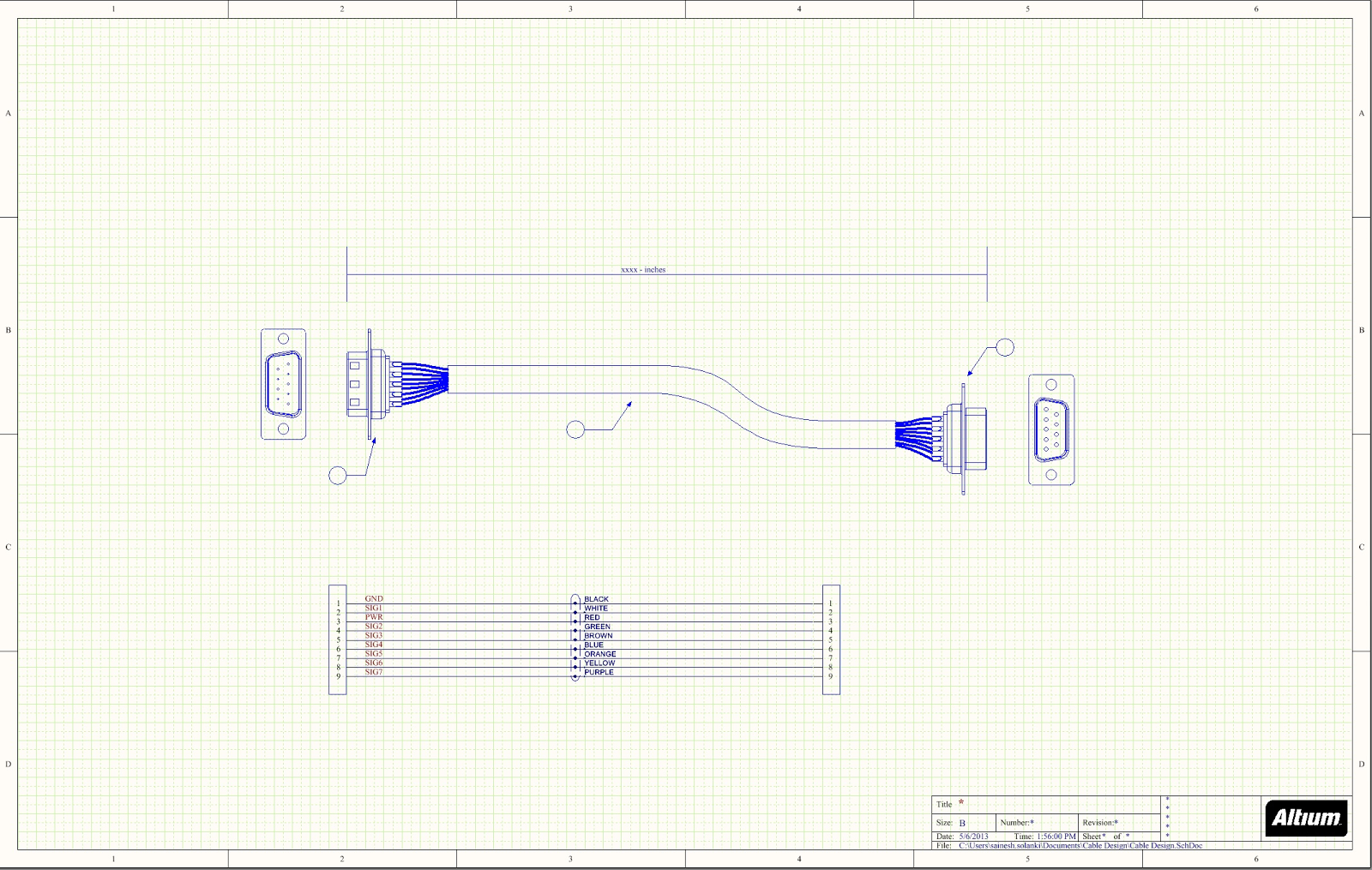

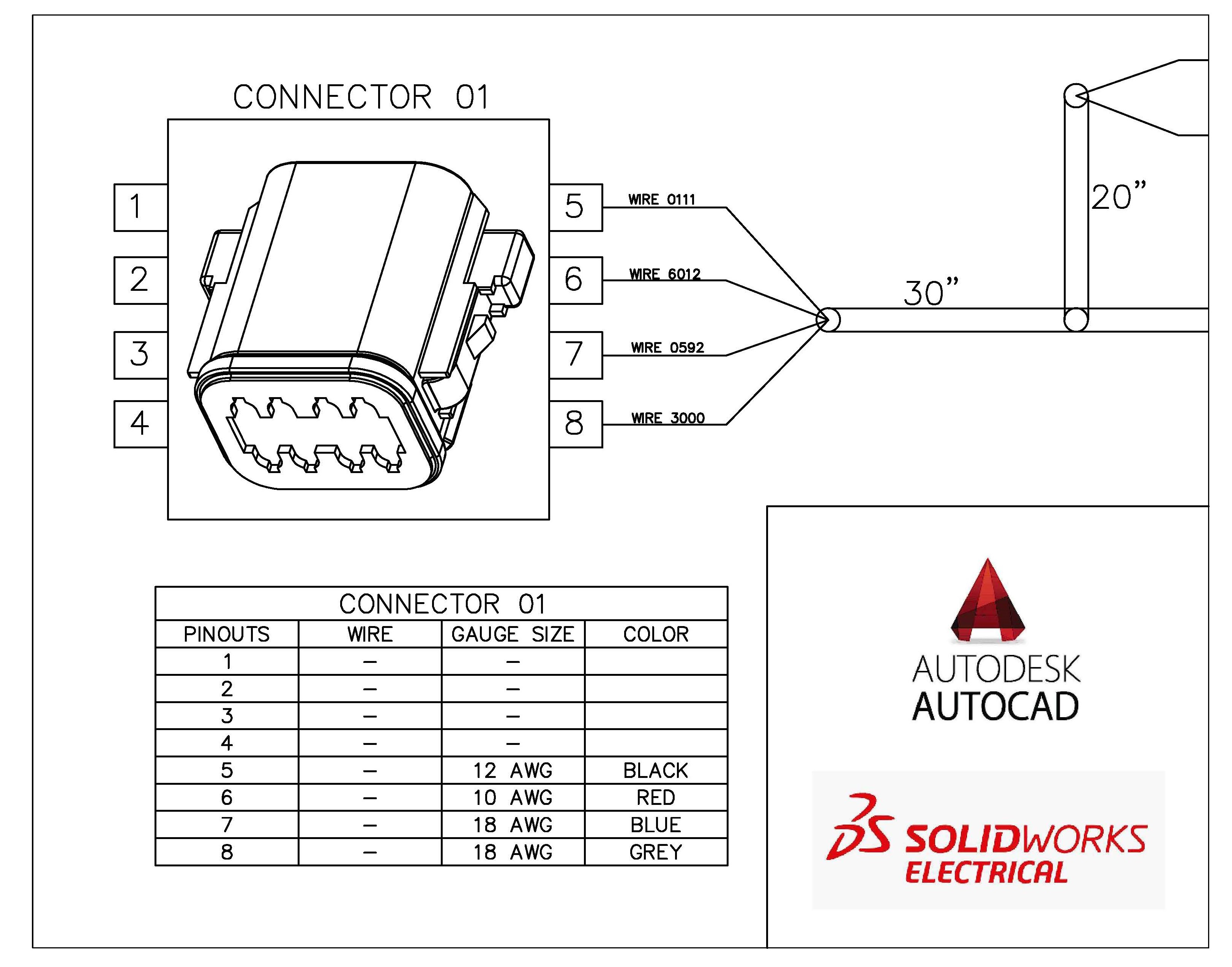

How to use Schematic CAD for Harness Drawings and Cable Assemblies

Cable Harness Design OPTIMAL CONNECTIVITY UAE

Wire Harness Design with SOLIDWORKS Electrical 3D

custom auto wiring harness hooha harness

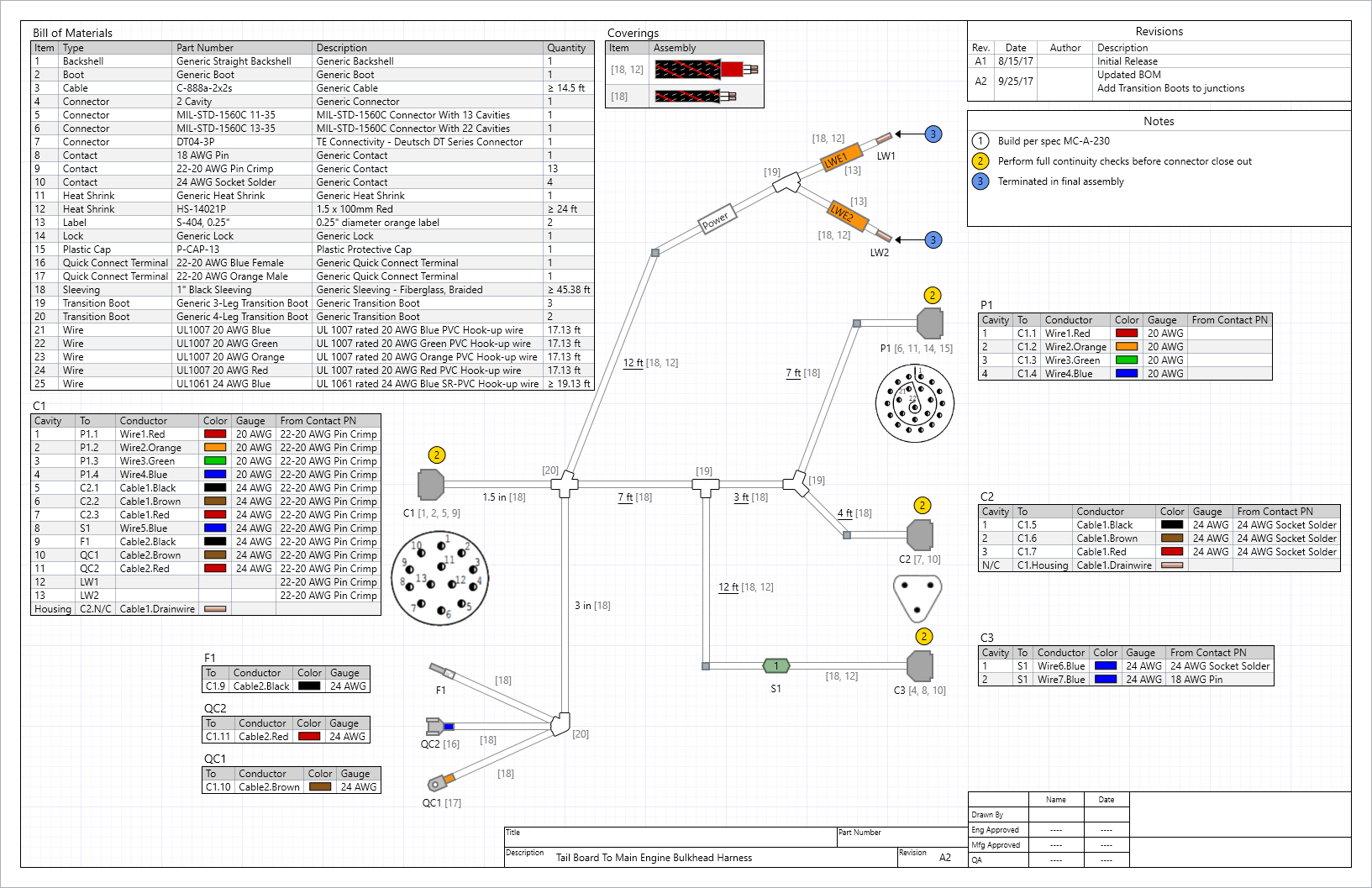

Wire Harness and Cable Assembly Drawing Best Practices

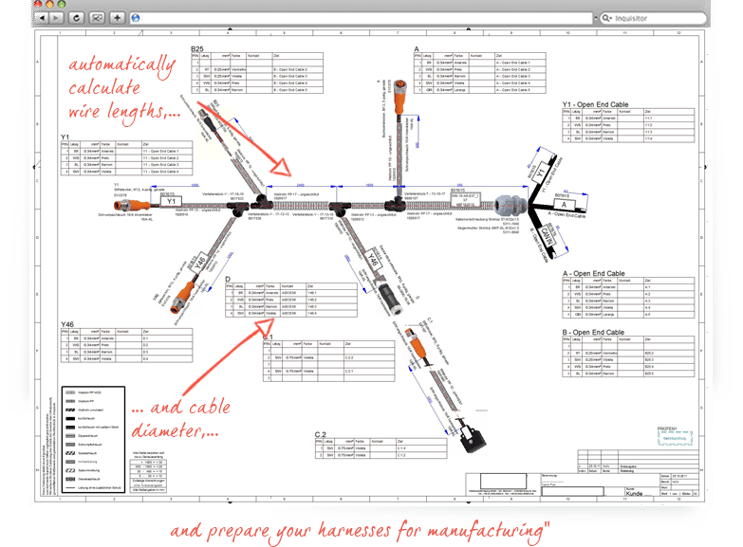

ECAD for Easy Wiring Harness Industrial Design

SOLIDWORKS Electrical Advanced Harness Drawings

8 Circuit Wiring Harness Diagram

wire harness drawing standards hooha harness

Wire Harness Design Absolute Electronics Services

Web Wirely Is A Wiring Harness Tool That Allows The User To Enter The Logical Connections For A Wiring Harness And Then Generates Beautiful Wiring Diagrams With Synchronized Documentation.

Requirements And Best Practices Include These General Items.

Connectors And Their Associated Parts Associated Parts Of Splices Associated Parts Of Connection Points Crimps Layout Labels

Lastly, We’ll How Automation Is Influencing Wire Harness Manufacturing.

Related Post: